Plenty of pictures here.(fwiw)

https://imageevent.com/time_warp1959/motorcycle/mgmodsI left the studs in when I did that modification but had to clock it up twice being turned 180 degrees on the table. ( I would only remove the studs if you have to)

Double hard wood decking screwed together then fixed to the the block.

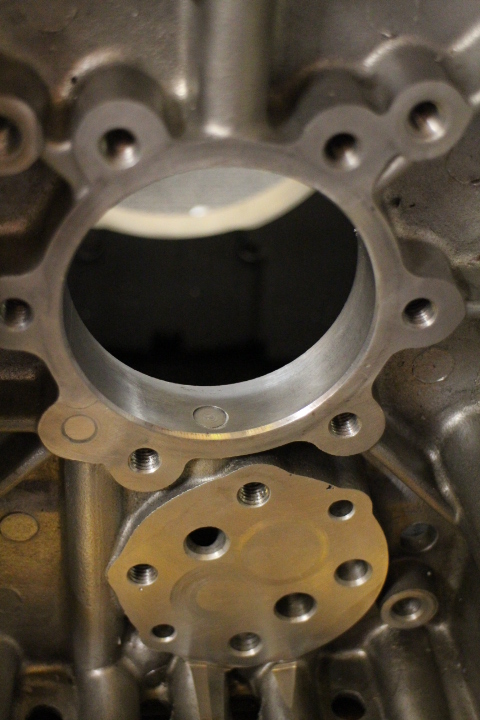

The engine case base was then fixed to the table and the wood face milled.

That turned out very accurate when the then inverted case was clocked on the sump face.

It took so long this pic is in NSW.

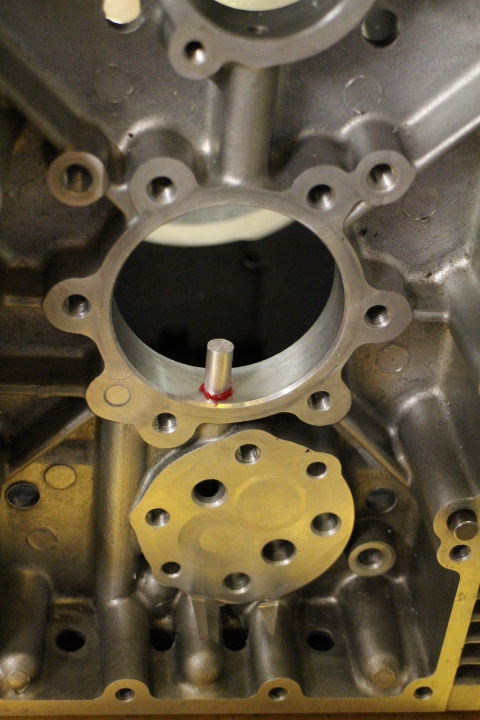

When I bored the case for the 88mm cylinders I removed the studs.

I had to heat the area around the studs, if you are lucky you can put a alloy horse shoe strip (maybe 2mm thick) around the stud top thread with a nut run down onto it.

Vice grips with the convex jaws (not the flat ones) can then be locked onto the strip and the studs might come out.

The stud removal tool will most likely damage the stud when it locked in.

This pic is in QLD.

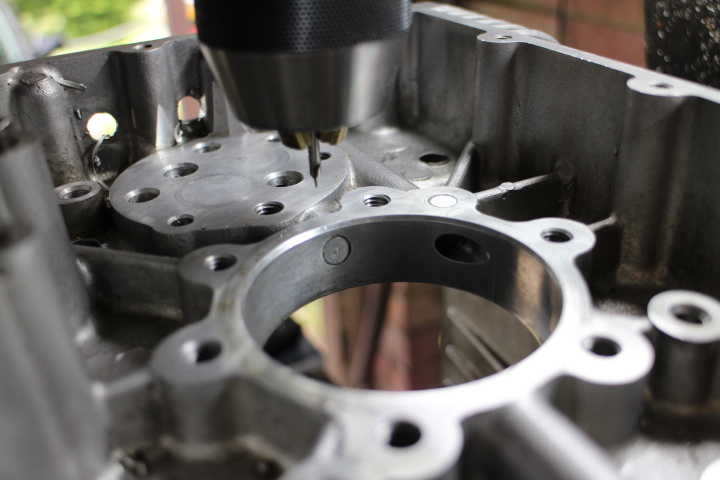

It reminds me that I made the quill power feed to do the boring.

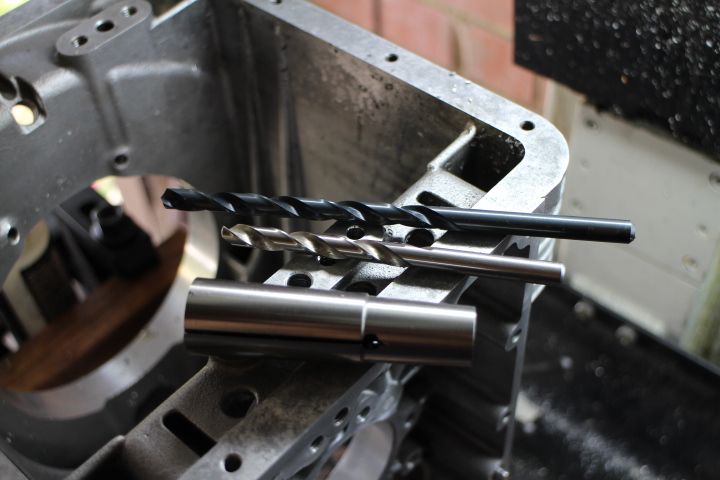

With the long series drill I used a collet over the chuck to gain the needed height.

I drilled one of the other holes 9.5mm with a shortened drill. (I think the 10mm is a wrong cross over for 3/8" on TOT)

You will see that when you measure the drillings.

I put studs in like this when I can (non destructive) and with a nut at the top on removal as needed.

Optional but I elected to block the old feed above the oil pump, Loctited and pinned at the front with a 3mm stainless steel grub screw.